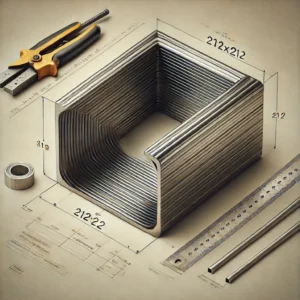

212 x 212 Square Tubing Dimensional Accuracy:

The specific 212 mm square measurements permit a well-balanced tons circulation and simplicity of combination right into building and construction structures.

What is 212 x 212 Square Tubing?

212 x 212 square tubes describes a hollow architectural area (HSS) with external measurements of 212 millimeters by 212 millimeters.

The tubes is generally made from steel or various other steels and is offered in differing wall surface densities, which straight influence its weight, stamina, and applications , Comprehending:

Features, Applications and Advantages

- The 212×212 square tubing is a durable alternative to the flexible square tubes. They play a significant role in architectural applications.

- These tubes have a consistent square form, providing security and load-bearing capacities in frameworks.

- The smooth or bonded production procedures guarantee integrity and fulfill commercial criteria, and you need ASTM A500 or EN criteria for steel tubes.

Wall Surface Thickness Variability:

Typical wall surface densities for this dimension vary from 6 mm to 16 mm, satisfying various degrees of architectural stamina demands.

Product Options:

The product can be utilized throughout sectors, from building and construction to production, many thanks to its flexibility.

Technical Considerations When Choosing 212 x 212:

Square Tubing Wall Surface Thickness:

Thicker wall surfaces boost toughness and weight. For example, a 10 mm wall surface is optimal for commercial load-bearing, whereas thinner wall surfaces fit lighter applications.

Bridges and Infrastructure:

Its high strength-to-weight proportion makes it appropriate for bridges, trusses, and facilities where security is critical.

Advantages of Using 212 x 212 Square Tubing

Toughness and Stability:

Square tubing consistent geometry also makes certain weight circulation, decreasing stress and anxiety factors and boosting the life expectancy of frameworks.

Renewable resource:

Wind turbines, photovoltaic panel installs, and various other renewable resource installments commonly utilize these tubes for their stamina and weather condition resistance.

Longevity of 212*212 square tubing:

Immune to contortion under hefty tons, it carries out incredibly well-sought-after atmospheres.

Relieve of Fabrication:

Square tubing /tubes work with reducing, welding, and boring, streamlining its personalization for particular applications.

read about : 2 x 2 square tubing

Applications of 212 x 212 Square Tubing

Architectural Frameworks:

- In industrial and commercial structures, this dimension is made use of in structures for roofing systems, columns, and durable support groups.

Visual Appeal:

- The tidy, geometric lines of square tubes use a streamlined look, especially in contemporary building layouts.

Equipment and Equipment Frames:

- The tubes work as a foundation for hefty equipment, making sure of longevity under continuous tension.

Transportation Industry:

- In trailers and transportation lorries, 212 x 212 square tubing adds to architectural rigidness and lightweight layouts.

Carbon Steel:

- Known for its stamina and cost-efficiency, it is extensively utilized for basic building and construction.

Stainless-steel:

- Provides rust resistance, making it perfect for outside or high-moisture atmospheres.

Galvanized Steel:

- Adds a zinc layer to avoid corrosion, which is best for lasting sturdiness.

High Load Capacity:

- The 212×212 square tubing is ideal for big jobs because of its size and structural stability.

Cost-Efficiency:

- Square tubing is more efficient than other products, such as strong bars and I-beams, but they’re also cheaper.

Product Grade:

- Tips for Working with 212 x 212 Square Tubing Reducing:

- Make use of a bandsaw or plasma cutter for tidy, specific cuts. Guarantee the blade works with the product quality to avoid bending or unequal sides.

- For strength-focused tasks, think about Grade S355 steel. For deterioration resistance, choose stainless-steel qualities like 304 or 316.

Welding Compatibility:

Make sure the product quality straightens with your welding strategies. Some qualities need pre-heating or certain filler products. For thorough lots of graphs or product requirements, consult your neighborhood provider or design standards to make the very best choice customized to your demands.

Why Choose 212 x 212 Square Tubing for Your Project?

If your job requires an equilibrium of stamina, longevity, and versatility, 212 x 212 square tubes is a superb option.

Its consistent form and a wide variety of product alternatives permit smooth assimilation right into any framework. Whether you’re building a business structure, enhancing a framework, or developing equipment, this tube dimension offers integrity and long-lasting efficiency.

Lots Calculations:

Euler’s FEA software or the crucial lot (ESS) program can be used to determine the tube’s capacity for bearing load. Environmental Factors: Galvanized steel or stainless steel is essential in environments that are destructive to prevent corrosion.

Welding:

MIG or TIG welding functions well for steel square tubes. Constantly tidy the surface area to eliminate any impurities that can influence the weld.

Surface area Coating:

Apply paint, powder finishing, or galvanization for included security versus ecological wear.

Transport:

Offered its dimension and weight, guarantee correct handling tools, like forklifts or cranes, to relocate and mount the tubes securely.

Comparison: 212 x 212 Square Tubing vs. Other Tubing Sizes

| Feature | 212 x 212 Tubing | 100 x 100 Tubing | 250 x 250 Tubing |

| Strength | High | Medium | Very High |

| Applications | Heavy-duty | Medium-duty | Extreme-duty |

| Cost | Higher | Lower | Higher |

| Weight Efficiency | Balanced | Lightweight | Heavier |

| Fabrication Ease | Moderate | Easy | Moderate |

The 212 x 212 size strikes a balance between strength and versatility, making it ideal for a wide range of structural projects.

Conclusion:

Why 212 x 212 Square Tubing is actually the Ideal Choice:

The 212 x 212 square tubing is much more than just a structural material– it is actually a foundation of stamina, flexibility, and cost-efficiency. Its consistent geometry ensures resilience, even under hefty lots, while the assortment of material and wall structure thickness choices permit it to become tailored for varied applications. Coming from modern-day home concepts to commercial machines and commercial infrastructure, its flexibility makes it essential.

Selecting 212 x 212 square tubing indicates purchasing a dependable, lasting option for your project. Whether you prioritize load-bearing capacity, oxidation protection, or ease of fabrication, these tubes deliver unequaled performance. With proper preparation and mindful product variety, you may optimize its possibility, ensuring your project’s effectiveness for several years to find.

I learned a lot from your content, thank you

Thanks a lot for your feedback