Fire Hose Quick Connect Fittings: The Ultimate Overview

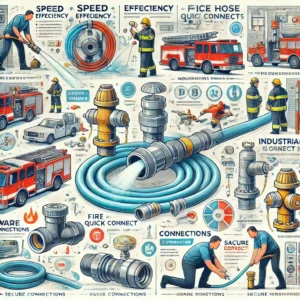

Fire safety tools must always be ready for activity, and fire hose quick connects fittings play an important duty in making certain swift and effective emergency feedback. These fittings enable quick and protected links between fire hoses, water resources, and nozzles, conserving valuable seconds during a fire. In this extensive guide, we’ll discover whatever you need to know about fire hose quick-connect fittings, including their types, uses, maintenance, and troubleshooting.

What Are Fire Hose Quick Connect Fittings?

Fire hose quick connect fittings are specialized combining tools that make it possible to fast and protect add-ons or detachment of fire tubes and accessories. Created to guarantee simplicity of use under pressure, these fittings are important for:

- Emergency efficiency: Quick links reduce configuration time in important scenarios.

- Compatibility: They connect various tools like hose pipes, hydrants, and pumps.

- Sturdiness: Built to endure high pressures and severe conditions.

Kinds Of Quick Connect Fittings

Threaded Couplings:

- Call for screwing to safeguard.

- Commonly used with standard fire pipes.

Storz Couplings:

- Include a non-threaded, symmetrical design.

- Allow for faster links and are widely utilized in modern-day fire systems.

Camlock Fittings:

- Run with bars for quick attachment and detachment.

- Suitable for linking hose pipes to pumps or containers.

Snap-Tite Couplings:

- Use a push-and-lock device. Make sure protected and leak-free links.

- Each type has unique applications, making it crucial to select the right one based on your requirements.

Usual Uses and Benefits of Fire Hose Quick Connect Fittings

Below are some uses of fire hose quick connect fitting

Applications

- Firefighting: Enable smooth connections for water shipment during emergencies.

- Industrial Settings: Used in chemical plants and manufacturing facilities for moving water or various other fluids.

- Irrigation Systems: Facilitate quick hose arrangement for large-scale irrigation.

- Local Water Systems: Aid in connecting pipes to hydrants for maintenance tasks.

Advantages

- Rate: Drastically decreases the time called for to set up or take apart pipes.

- Dependability: Provides secure and watertight connections under high-pressure problems.

- Adaptability: Compatible with numerous hose dimensions and materials.

- Longevity: Constructed from materials like aluminum, brass, or stainless steel, making certain durable performance.

- Practical Advice: Choosing and Maintaining Quick Connect Fittings

How to Choose the Right Fittings

Consider Compatibility:

- Match the suitable type with your hose and tools.

- Confirm size requirements to make sure the correct fit.

Material Selection:

- For high-pressure atmospheres, select stainless steel.

- Brass fittings are suitable for rust resistance in damp conditions.

Usage Environment:

- Select heat-resistant products for firefighting applications.

- For industrial usage, make certain compatibility with the liquids being delivered.

Certifications: Search for fittings that meet NFPA (National Fire Protection Association) criteria.

Upkeep Tips Routine Cleaning:

Remove debris and dirt to avoid deterioration.

Examine for Damage: Check for fractures, leakages, or deformities before and after usage.

Lube Moving Parts: Apply suitable lubricants to make certain smooth procedures.

Shop Properly: Keep fittings in a completely dry, tidy environment to stay clear of deterioration.

FAQs About Fire Hose Quick Connect Fittings

Q: How do I recognize if my fittings are compatible with my fire hose?

A: Check the dimension, string type, and combining system of your hose and installation. Describe the supplier’s specs for specific information.

Q: What should I do if my quick connect suitable leaks?

A: Inspect the suitable for cracks or worn seals. Replace harmed parts and ensure links are tightened properly.

Q: Can I make use of quick-connect fittings with any type of fluid?

A: Most fittings are made for water, yet industrial variations might manage chemicals or other fluids. Always verify material compatibility.

Q: How frequently should fittings be checked?

A: Conduct visual examinations prior to each use and schedule thorough checks each year to ensure optimal efficiency.

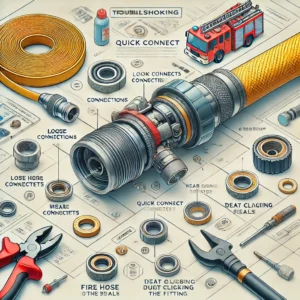

Troubleshooting Common Issues For Fire Hose Quick Connect Fitting

Dripping Connections:

Solution:

- Check for used gaskets and change them.

- Make sure couplings are tightened properly.

Difficulty Connecting:

Solution:

- Clean particles from the coupling mechanism and oil-relocating parts.

Corrosion or Rust:

Solution:

- Use corrosion-resistant materials and shop fittings in a dry environment.

Loose Couplings:

Solution:

- Replace worn-out securing devices and inspect for appropriate fit.

Final thought

Fire hose quick connect fittings are vital for reliable firefighting and commercial applications. By understanding the kinds, benefits, and upkeep tips described in this overview, you can ensure your devices continue to be in top problem and are all set to perform when it matters most.

Put in the time to inspect and keep your fittings consistently. If you’re trying to find premium fire hose quick-connect fittings, check out relied-on suppliers that meet safety, security and efficiency standards. Remain prepared, and stay risk-free!