The Ultimate Guide to Rubber Tubing:

Every Little Thing You Need to Know

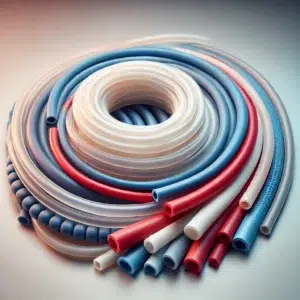

Rubber tubing is one of the best and most versatile materials available. From clinical gadgets and auto systems to commercial applications and even DIY jobs, rubber tubes also have a great part in transporting fluids, gases, and much more. Its mix of versatility, resilience, and resistance to different ecological elements makes it a dependable selection throughout industries.

In this ultimate overview concerning rubber tubes, we’ll cover every little thing you require to know– from its kinds and applications to how to pick the right one and keep it for optimum efficiency. let’s dive into the sea of tubing !

What Exactly is Rubber Tubes?

At its core, rubber tubing is an adaptable, hollow tube made from different rubber compounds . It’s generally made used to move fluids, gases, or powders, thanks to its elasticity, toughness, and ability to endure deterioration. What sets rubber tubing apart is its convenience.

Depending upon the sort of rubber used, it can take care of extreme temperatures, withstand chemicals, and even sustain exterior conditions. That’s why it’s the best service for everything from high-pressure systems in lorries to food-grade applications in the kitchen area.

Sorts Of Rubber Tubing Not all rubber tubbing is produced equal. Each type has special homes that make it fit for detailed applications. Right here’s a failure of one of the most usual types:

Natural Rubber Tubes Feature:

This deals with outstanding elasticity, high tensile toughness, and solid abrasion resistance. All-natural rubber tubes are versatile and can take care of a broad temperature variety.

Makes use of Suitable for clinical applications like IV lines and low-pressure liquid systems.

Limitations:

- It does not fare well versus UV light or ozone exposure, which can trigger destruction in time.

Nitrile Rubber Tubes attributes/features:

Buna-N is also known as nitrile, which is oil resistant rubber , gas and petroleum-based substances and element. It is durable and abrasion resistant.

Uses:

- Used in automotive, hydraulic and industrial systems, where resistance to oil and gas is important.

Limitations:

- The rubber adaptability decreases significantly at lower temperature levels as compared to other rubbers.

Silicone Rubber Tubes Quality:

Silicone tubes are actually acknowledged for its own adaptability, strength in severe temperatures, and resistance to UV rays and ozone.

Uses:

- Preferred for clinical and food-grade uses because of its biocompatibility and capability to delay versus sanitation.

Limitations:

- Silicon tubes are actually even more expensive than the majority of a variety of other styles.

EPDM Rubber Tubes Residence:

Ethylene Propylene Diene Monomer (EPDM) cylinders professionals withstanding UV rays, ozone, weathering, and extreme temperatures.

Makes use of:

- Perfect for exterior applications, particularly in the automotive and property markets.

Limitations:

- It does not manage oils or even gas.

PVC Rubber Tubes Feature:

PVC tubing is lightweight, economical, and immune to chemicals, although it’s much less versatile than various other types.

Utilizes:

- Appropriate for water and air transport in commercial and medical applications.

Limitations:

- PVC tubing can end up being breakable with age and lacks the versatility of natural or silicone rubber.

Neoprene Rubber Tubes Feature:

Neoprene is a durable material that resistible against water and give us exceptional result, oils and abrasion. For outdoor purposes, this material is an outstanding solution. It’s extremely durable. Used in electrical, automotive, refrigeration and other systems.

Limitations:

- Not suitable for extreme temperatures.

read about : rubber hose

Why Choose Rubber Tubes?

Rubber tubes attract attention because of their distinct mix of advantages:

Flexibility:

- It bends and extends conveniently, making it perfect for rooms with tight turns or movement.

Toughness:

- Resistant to abrasions, impacts, and various chemicals, rubber tubes commonly last longer than options like plastic.

Convenience:

- Handles a large quantity of substances, consisting of water, oil, gas, and chemicals.

Temperature Resistance:

- Particular kinds, like silicone, can endure extremely hot or chilly conditions without breaking down.

Personalization:

- Add supports and adjust wall density, size or size to meet certain requirements.

Rubber Tubing has many applications:

Common Application Of Rubber Tubing

Rubber tubing isn’t just for industrial use—it’s found everywhere, from hospitals to home workshops. Here’s a look at some common applications:

Medical and Healthcare

- Rubber tubing is used in IV lines and catheters, as well as blood transfusion systems and respiratory devices.

- Its biocompatibility and ability to hold up against sterilization make it important in clinical equipment.

Automotive

- Sector Gas lines, brake pipes, and radiator systems rely on rubber tubing for its resistance to warmth, stress, and chemicals. It’s a key element in keeping cars running smoothly and safely.

Industries and Manufacturers:

- Industries also use rubber tubes to serve different purposes, including cooling systems, hydraulic systems, and others. Rubber tubing’s durability and versatility are essential in environments with high demand.

Food and Beverage Industry

- To transport gases, liquids and oils Food-grade rubber tubing is used in the industries of beverages . It is ideal because of its resistance to contamination and sterility.

Home and Do It Yourself

- Projects From yard pipes to fish tank tubes, rubber tubes are a typical selection for home usage due to their versatility and durable performance.

- Electronics In electronic devices, rubber tubing works as insulation and protects the circuitry from ecological damage.

- This is especially important in outdoor and rough problems. How to Choose the Right Rubber Tubbing Selecting the best rubber tubing depends on your application.

Bellow’s what to consider:

1. Chemical Compatibility:

Ensure the tube’s material is resistant to the materials it will transfer.

For example, oils are compatible and friendly with nitriles, while silicone is excellent for food-grade or medical use.

2. Temperature Level Array:

The environmental condition must match the tube requirements. Silicone takes care of extreme temperatures, while EPDM executes well in exterior setups.

3. Stress Ranking:

Ensure the tubing can endure the operating pressure without failing.

4. Adaptability:

Consider just how much flexing and navigating the tubes will require.

5. Longevity:

Evaluate wear and tear dangers, particularly if the tubing will certainly be exposed to abrasion, UV light, or chemicals.

Size and Modification:

Installation and Maintenance Tips: Make sure the tube’s diameter and wall thickness match your system requirements. Rubber Tubing Installation and Maintenance Tips:

Setup Tips Cutting:

Used a sharp blade for tidy cuts to keep away from leakages or weak points.

- Fitting: The adapter must be snug fit; for additional security utilize clamps if required.

- Avoid Kinks: sharp bends must be avoided to avoid limiting circulation.

Maintenance Tips Routine Inspections:

Check for fractures, wear, or other indications of destruction, specifically in harsh problems.

- Cleansing: Tidy tubes as needed to stop clogs or contamination.

- Safeguard from UV and Ozone: Shop tubes away from straight sunlight to prevent premature aging.

- Premature aging should be caused by straight sunlight on shop tubes. if you want to prevent your tubes from premature aging, stay away your tubes from sunlight.

- Fixing Usual Issues: Even with appropriate treatment, problems can arise.

Here’s just how to manage them:

Leakages:

- Evaluate for wear, incorrect links, or damage. If it’s required, please change the tubes.

Kinking:

- Replace the tube if it bends sharply or redirects it to avoid strain.

- Select the right rubber tubing for the project you’re working on, whether it is in the automotive or medical industries or if you’re performing some simple DIY.

- Understanding how to install the product and its residential characteristics/features will help you increase performance and durability. You will be able to make an informed decision, and your system will run efficiently for years.

Rubber Tubes: Top 5 Questions & Answers

1. The rubber tubing can be made use of?

- for a variety of uses, including motor vehicle, commercial, medical and DIY.

2. How do I gauge rubber tubes?

- Procedure the interior dimension, outside diameter and wall structure thickness utilizing a leader.

3. Can rubber tubing easily stand up to high temperatures?

- Some kinds, like plastic and EPDM, are heat-resistant, making all of them best for heat requests.

4. Is rubber tubing safe to make use of along with meals and refreshments?

- Like plastic, the food-grade rubber pipe could be used for moving food and alcoholic beverages without hurting them.

5. how do I maintain rubber tubing?

- Avoid revealing the product to sunshine, and examine it frequently for fractures or even put it on.

Conclusion:

Rubber tubing has a large range of uses and is used in a number of fields. It supplies adaptability, resilience and customization for many applications. Opt for the greatest rubber tubing for your job, whether you remain in the automobile or healthcare industry. You can improve the efficiency of your unit and its long life by comprehending what sorts of items are actually available, their attributes, and how to mount all of them accurately.

This quick guide will certainly assist you in making the right decisions to maintain your body competing for several years. To make the appropriate choice, you need to have to know the rudiments of rubber tubing.

After reviewing the manual carefully, you will definitely be able to determine different forms of tubing and analyze their treatment, along with their benefits. This guide will assist you in making notified choices that are sure to increase the productivity and toughness of your job.

7 Responses