A Comprehensive Guide to Hose Valves: Types, Applications, and Advantages

What Are Hose Valves?

Kinds Of Hose Valves

1. Ball Valves

Ball valves feature a round closure unit with a hole in the centre. When the valve manager is turned, the hole straightens with the flow path, enabling liquid or gas to go through. Turning the deal once more blocks the flow.

Features:

- Quick to open up and close.

- Outstanding for on/off control.

- Very little pressure drop when open.

Applications:

- Horticulture systems.

- Industrial applications requiring rapid shutoff.

2. Gate Valves

Gate valves make use of a level or wedge-shaped gateway to control circulation. When eviction is raised, fluid streams openly; lowering eviction obstructs the passage.

Functions:

- Suitable for full-flow applications.

- A slow procedure provides controlled closure.

Applications:

- Agricultural irrigation.

- Pipes systems.

3. Examine Valves

Examine valves are one-way valves that prevent heartburn. They immediately open when liquid moves in the desired direction and close when the circulation reverses.

Attributes:

- Prevents contamination or damage from opposite circulation.

- Runs instantly.

Applications:

- Water distribution systems.

- Pumping terminals.

4. Butterfly Valves

Butterfly valves include a turning disc that controls circulation. Turning the manager revolves around the disc, which either obstructs or allows flow.

Features:

- Lightweight and small.

- Helpful for throttling and shutoff.

Applications:

- HVAC systems.

- Chemical handling plants.

5. Needle Valves

Needle valves are developed for accurate circulation control. They include a slender, tapered factor that fits into a seat to regulate circulation prices carefully.

Functions:

- High precision for low-flow applications.

- Outstanding for strangling.

Applications:

- Laboratory experiments.

- Fuel lines.

6. Hose Bib Valves

Likewise known as outside faucets, these valves are generally made use of in property settings to regulate water flow to yard hoses.

Functions:

- Easy to run.

- Durable versus outdoor problems.

Applications:

- Garden watering.

- Loading swimming pools and fish ponds.

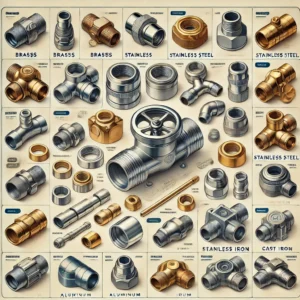

- Products Used in Hose Valves

Typical materials include:

1. Brass Residence:

- Quality: Corrosion-resistant, sturdy, and ideal for high-pressure applications.

- Applications: Gardening, pipes, and commercial usage.

2. Stainless-steel

- Quality: Highly resistant to deterioration, warmth, and pressure.

- Applications: Chemical handling and food-grade systems.

3. PVC (Polyvinyl Chloride).

- Quality: Lightweight, easy to carry, cost-effective, and corrosion-resistant.

- Applications: Low-pressure water systems and irrigation of liquid.

4. Lightweight aluminum.

- Properties: Lightweight and reasonably corrosion-resistant.

- Applications: Automotive and aerospace sectors.

5. Nylon and Polypropylene.

- Characteristic: Chemical-resistant and lightweight.

- Applications: Laboratory settings and chemical transfer systems.

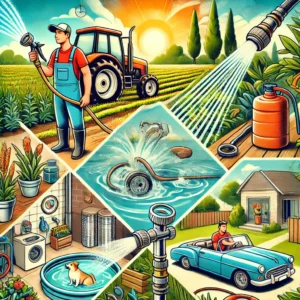

Secret Applications of Hose Valves.

1. Farming and Irrigation.

- Hose valves control water flow for watering systems, ensuring crops get the right amount of water without waste.

2. Residential Use.

- In homes, hose valves prevail in garden hoses, exterior water faucets, and swimming pool upkeep systems.

3. Industrial Applications.

- Industries utilize hose valves to manage the flow of gases and liquids in making procedures, chemical plants, and refineries.

4. Medical care and Laboratories.

- In medical and laboratory settings, hose valves manage accurate fluid and gas circulation in fragile treatments and experiments.

5. Automotive Industry.

- Hose valves are essential in car air conditioning systems, fuel lines, and cooling units.

Benefits of Using Hose Valves.

-

- Improved Flow Control: They permit accurate control over flow rates, lowering waste and boosting effectiveness.

- Security: Valves prevent backflow and leakages, ensuring safety and security in critical applications.

- Convenience: Available in different kinds and products, hose valves can be tailored to meet details demands.

- Toughness: High-quality valves endure severe temperature levels, stress, and destructive materials.

- Ease of Maintenance: Many hose valves are designed for very easy disassembly and cleaning.

Maintenance Tips for Hose Valve.

To ensure a long life and optimal performance, normal upkeep is necessary. Here are some pointers:

Clean Regularly:

- Remove particles and sediment that might obstruct the valve.

Inspect for Leaks:

- Periodically examine seals and connections for leakages.

Lube Moving Parts:

- Use suitable lubricants to stop wear and tear on relocating components.

Replace Worn Parts:

- Replace harmed or damaged parts promptly.

Store Properly:

- During off-seasons, shop valves in a dry, amazing area to avoid rust.

How to Choose the Right Hose Valve.

- Application: Consider the purpose and flow requirements.

- Material Compatibility: Ensure the valve product is appropriate for the liquid or gas being used.

- Pressure and Temperature Ratings: Match the valve’s capacities to your system’s operating problems.

- Dimension: Choose a valve that fits your hose size and flow demands.

- Type of Control Needed: Determine if you need accurate control, on/off performance, or backflow avoidance.