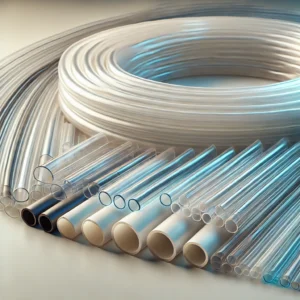

Plastic Tubing: Plastic Tube

The Complete Guide to Plastic Tubing:

Types, Applications, and Benefits Plastic tubing can be used in a variety/quantity of markets, including health care, food handling, automotive, and production. The versatility of the material, its longevity and its resistance to chemicals make it an excellent/greatest choice for a wide range of applications.

This overview checks out the numerous kinds of plastic tubing, its production procedures, typical usages, and the advantages it supplies. By incorporating appropriate keywords, this short article guarantees an SEO-optimized experience for those wanting to discover more about this necessary product.

What is Plastic Tubing?

Plastic tubing is a hollow round framework made from polymer-based products like PVC, polyethylene, polyurethane, or nylon. It is developed to move liquids, gases, or solids while keeping adaptability and stamina. Plastic tubing can be found in various forms, dimensions, and formulas, satisfying a wide variety of commercial and industrial applications.

Sorts Of Plastic Tubing:

1. PVC Tubing

Polyvinyl chloride (PVC) tubes are among the most preferred kinds, understood for their price, chemical resistance, and openness. It is utilized thoroughly in clinical gadgets, food and drink handling, and chemical transportation.

Advantages:

- High quality for noticeable liquid tracking Super chemical and rust resistance

- Budget-friendly, less costly, and very easy to take care of.

2. Polyethylene Tubing :

Polyethylene tubes provide adaptability, lightweight building and construction, and high chemical resistance. It is frequently utilized in water system lines, watering systems, and pneumatically-driven applications.

Benefits:

- Lightweight, easy installation and resistant to chemicals.

- Food-grade alternatives are readily available.

3. Polyurethane Tubing.

Polyurethane tubing is highly versatile, resistant, and immune from abrasion. It’s ideal for applications such as pneumatically driven systems, gas lines, etc.

Benefits:

- Excellent versatility and twist resistance.

- High tensile strength. Ideal for reduced- and high-pressure systems.

4. Nylon Tubes –

Nylon tubing is highly valued because of its durability, warmth resistance and low wetness absorbency. The airbrake system, automobiles, and commercial vehicles all use it extensively.

Advantages:

- High stress and temperature level resistance.

- Reduced wetness absorption Lasting and resilient.

5. Silicone Tubing:

Silicone tubes are soft, heat-resistant, and biocompatible, making them vital in clinical and food-grade applications.

Advantages:

- Fish tanks and Gardening.

- Adaptable plastic tubing is vital for fish tank oxygenation, watering systems, and hydroponic arrangements.

- Its capability to stand up to water and UV direct exposure guarantees long-lasting efficiency.

Automotive and Aerospace.

In the automobile and aerospace markets, plastic tubing made use of gas lines, hydraulic systems, and airbrake systems. It is lightweight and resistant to put on, adding to enhanced performance.

Benefits of Plastic Tubing:

1. Adaptability:

- Plastic tubes supply phenomenal versatility, permitting very easy setup and the ability to move in limited areas.

2. Food and Beverage:

- Plastic tubes can be used in environments that are food grade for milk transfers, drink dispensers, and handling of food.

- PVC, silicone and other products are safe for health.

- A safe and biocompatible product with excellent temperature resistance.

- Adaptable, simple and easy to decontaminate.

3.Teflon Tubing (PTFE):

- Teflon tube is known for its chemical resistance and non-stick properties.

- It’s used in laboratories and for chemical handling.

Advantages:

- The surface area is exceptionally smooth.

- Thermal and chemical resistance is high.

- Non-reactive, resilient and non-reactive.

Uses of plastic tubing:

1. Medical and healthcare:

In medical applications, plastic tubes can be used for IV lines, medical instruments, and catheters. The sterility of the tubing, its versatility and its compatibility with sanitation methods make it ideal for critical applications.

Industry and Manufacturing:

Commercial setups use plastic tubing to promote pneumatically driven systems, chemical transport, and water treatment. The flexibility of the plastic tubes allows it to handle different stress levels and temperatures.

Research Laboratory and Chemical Processing:

In labs and chemical factories, the use of plastic tubes resistant to chemicals, such as PTFE or polyethylene, allows for the safe transport of gases and other harmful materials.

2. Chemical Resistance

Plastic tubing is resistant to acids and chemicals.

3. Resilience:

The plastic tubes are resistant to UV exposure and temperature variations, ensuring a long-lasting product.

4. Lightweight:

The light weight of plastic tubing makes it easy to transport and install while also minimizing the overall system weight for applications such as automobiles and aerospace.

5. Economical:

Compared to steel tubes, plastic tubes are a lot more economical without endangering efficiency for many applications.

6. Customizability.

Plastic tubing can be produced in a range of dimensions, shades, and formulas to satisfy details sector needs.

Application Requirements:

Identify the kind of liquid or gas the tubes will certainly carry and the operating problems.

Product Compatibility:

- Choose a material that is resistant to any materials the product will bring.

The temperature range:

- Make sure the tubes are able to withstand the temperatures. Stress Tolerance

- Check that tubes are able to withstand the required stress levels.

Qualifications:

- When submitting applications that require safety or security, look for FDA, NSF or ISO certification.

Maintenance and longevity:

- How to maximize the lifespan of plastic tubes:

Shot molding:

- By injecting a liquified material into a mold, shot molding can be used to create specific tube shapes or installations.

Plastic Tubes: New Developments:

Plastic tubing is a market that has seen the introduction of technologies such as:

How to choose the right plastic tubes.

Consider these factors when choosing plastic tubes:

- Regularly clean tubes to prevent clogs and contamination.

- Check for signs of wear or damage.

- Avoid exposing non-UV-resistant tubes to prolonged sunlight.

- When signs of damage appear, change the tubes as soon as possible.

Ecological Considerations.

Plastic tubes have gathered objection for their ecological effect, largely as a result of their dependence on nonrenewable fuel sources and minimal biodegradability.

Nonetheless, producers are progressively taking on lasting methods, such as reusing and creating bio-based plastics. Picking recyclable or recyclable tubes can help in reducing ecological impacts.

Usual Manufacturing Processes.

Extrusion:

- One of the most typical techniques for generating plastic tubes, extrusion, entails melting plastic pellets and forming them right into a continual tube, making use of a die.

Blow Molding:

- For hollow and larger-diameter tubes, impact molding is utilized by blowing up liquified plastic right into a mold and mildew dental caries.

Bio-based Plastics:

- Tubing is made from renewable energies.

Advanced Coatings:

- Improved resistance to chemicals and abrasion.

Smart Tubing:

- Embedded sensing units for real-time surveillance of liquid circulation and stress.

Last Thoughts:

Plastic tubing stays a vital part throughout markets because of its convenience, toughness, and cost. Comprehending the different kinds, applications, and benefits guarantees you can pick the ideal tubes for your requirements. As technical improvements proceed, plastic tubing will certainly develop to satisfy the expanding of modern-day applications.