Why Platinum-Cured Silicone Tubing is the Industry Gold Standard”

Platinum-cured silicone tubing is a top-tier remedy for different sectors calling for high-performance, sanitary, and long-lasting tubing. Popular for its pureness, adaptability, and durability, this tubing kind is crucial in markets like drugs, food and drink, clinical tools, and a lot more.

This overview looks into the information on platinum-cured silicone tubing, aiding you in recognizing its advantages, applications, and factors to consider for usage.

What is Platinum-Cured Silicone Tubing?

“Key Features You Can’t Ignore”:

Safe and Biocompatible:

- Meets rigid governing criteria for clinical and food-grade applications.

Warmth Resistance:

- Withstands temperature levels varying from -80 ° F to 450 ° F (or extra, depending upon the solution).

Chemical Resistance:

- Resistant to a large range of chemicals, consisting of acids, antacids, and solvents.

Versatility and Resilience:

- Remains versatile without splitting or setting in time.

Odorless and Tasteless:

- Ideal for applications where contamination of materials is an issue.

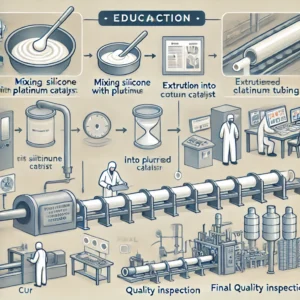

How Platinum-Cured Silicone Tubing is Made?

Advantages of Platinum Curing:

- No leachable or extractable.

- Much better thermal security.

- Greater tear resistance and prolongation. Superior quality for aesthetic surveillance of liquids.

Top Benefits of Choosing Platinum-Cured Tubing:

Pureness and Safety:

- Complies with FDA, USP Class VI, and ISO 10993 criteria. Without BPA, phthalates, and various other hazardous chemicals.

Thermal Stability:

- Maintains buildings throughout a vast temperature level variety. Appropriate for autoclave and heavy steam sanitation procedures.

Sturdiness:

- Stands up to aging, weathering, and UV direct exposure. Provides a much longer life span compared to various other sorts of tubing.

Non-Reactive:

- Does not present preference or smell to components. Chemically inert, making certain no contamination.

Adaptability and Strength:

- Very flexible, suiting limited bends and intricate setups. Holds up against duplicated sanitation cycles without breaking down.

Industries Relying on Platinum-Cured Silicone Tubing:

1. Drug and Biotech:

Made use of moving liquids, gases, and energetic components in medicine production. Crucial in bioprocessing and lab applications.

2. Medical Devices:

Suitable for catheters, water drainage tubes, and various other important clinical parts. Biocompatibility guarantees risk-free communication with body cells and liquids.

3. Food and Beverage Industry:

Perfect for moving fluids like milk, juice, and beer in high-purity atmospheres. Fulfills food-grade requirements for straight calls with consumables.

4. Industrial Applications:

Utilized in making procedures including heat or chemical direct exposure. Ideal for peristaltic pumps, seals, and gaskets.

5. Aerospace and Electronics:

Supplies insulation for electric parts. Utilized in systems subjected to severe temperature levels and stress.

Tips for Selecting the Right Tubing for Your Needs :

When choosing the appropriate tubing for your application, take into consideration the list below aspects:

Governing Compliance:

Look for FDA, USP Class VI, or ISO accreditations based on your application.

Dimension and Dimensions:

Internal size (ID), external size (OD), and wall surface density need to match your needs.

Temperature level Tolerance:

Make certain the tubing can manage the operating temperature level variety of your system.

Stress Rating:

Choose strengthened variations if the application entails high-pressure liquids.

Openness:

Usage clear tubing for aesthetic surveillance of liquid circulation.

Chemical Compatibility:

Confirm resistance to the chemicals made use of in your procedure.

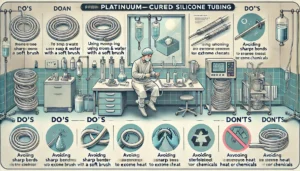

Care and Maintenance for Long-lasting Tubing:

Tips Appropriate treatment and upkeep are vital to expanding the life of platinum-cured silicone tubing:

Cleansing:

Use cosy water and light cleaning agents for cleansing. For sanitation, select autoclaving or chemical sanitization as advised by the producer.

Evaluation:

Frequently check for indications of wear, such as fractures or staining. Change tubing if any concession instability is found.

Storage space:

Shop in an awesome, completely dry location far from straight sunshine and ozone.

Adhere To Manufacturer Guidelines:

Abide by the use and Maintenance guidelines offered by the distributor. Distinctions Between Platinum Cured and Peroxide Cured

Silicone Tubing

Feature Platinum Cured Peroxide Cured Purity Higher (no byproducts) Lower (might leave deposits).

- Transparency Excellent Moderate.

- Flexibility Superior Good.

- Thermal Stability Higher Moderate.

- Cost More Expensive Less Expensive.

- Common Applications Medical, Pharma, Food Industrial, General Use.

Where to Buy Platinum-cured silicone tubing

.

Trustworthy providers of platinum-cured silicone tubing consist of:

- McMaster-Carr: Offers a variety of commercial and medical-grade alternatives.

- Cole-Parmer: Specializes in laboratory and commercial tubing.

- Amazon: Convenient for buying small amounts.

- Grainger: Supplies top-notch tubing for commercial applications.

Make sure it fulfills the need of your usage before buying any tubing. Check the needed qualifications and requirements.

Often Asked Questions (FAQs).

Q1: Is platinum-cured silicone tubing secure for food to get in touch with?

- Yes, platinum-cured silicone tubing is FDA-compliant and excellent for food-grade applications.

Q2: is it possible to deal with high-pressure applications?

- Criterion tubing can deal with modest stress. However, enhanced alternatives are readily available for high-pressure needs.

Q3: How does it contrast to various other kinds of silicone tubing?

- Platinum-cured tubing deals with premium pureness, toughness, and efficiency, particularly in delicate applications.

Q4: Can it be made use of in peristaltic pumps?

- Yes, its adaptability and resilience make it ideal for peristaltic pump systems.

Q5: Is it immune to chemical destruction?

- It is very immune to many chemicals yet might not work with solid acids or bases.