A Comprehensive Guide to Smoke Vinyl Tubing: Applications, Benefits, and Selection Tips

When it comes to versatile tubing solutions, smoke vinyl tubing has carved out a niche for itself in various industries. Known for its durability, transparency, and aesthetic appeal, smoke vinyl tubing is a popular choice for applications ranging from industrial setups to home projects. This article delves into everything you need to know about smoke vinyl tubing, including its properties, applications, types, and tips for choosing the best product for your needs.

What is Smoke Vinyl Tubing?

Smoke vinyl tubing refers to a type of flexible plastic tubing made from polyvinyl chloride (PVC) with a tinted or “smoke” finish. The smoke tint offers a semi-transparent appearance, allowing visibility of the contents while providing a sleek and professional look. This tubing is commonly used for transferring liquids, gases, or as protective covering for wires and cables.

Key Features of Smoke Vinyl Tubing

1. Durability:

- Smoke vinyl-tubing is resistant to abrasion, cracking, and general wear and tear, making it suitable for long-term use.

2. Flexibility:

- The tubing can bend and twist without kinking, ensuring smooth functionality in dynamic applications.

3. Transparency:

- The smoke tint allows partial visibility of the tubing’s contents, making it easier to monitor flow or cable placement.

4. Chemical Resistance:

- It is resistant to many chemicals, including oils and mild acids, enhancing its versatility.

5. UV Resistance:

- Some smoke-vinyl-tubing variants are designed to resist UV degradation, making them suitable for outdoor use.

6. Aesthetic Appeal:

- The tinted finish provides a polished look, ideal for applications where appearance matters.

Applications of Smoke Vinyl Tubing

1. Industrial Applications

- Smoke vinyl-tubing is widely used in industrial settings for fluid transfer, pneumatic systems, and cable management.

Examples:

- Fluid transportation lines in factories

- Air or gas lines in pneumatic systems

- Protective sleeves for electrical wires

2. Automotive Use

- In the automotive industry, smoke-vinyl tubing is used for fuel lines, vacuum lines, and wire harness protection.

Examples:

- Vacuum tubing in engine systems

- Covering for automotive wiring to prevent abrasion

- Coolant transfer lines

3. Home and DIY Projects

- Its flexibility and sleek appearance make smoke-vinyl tubing a favorite for home improvement and DIY projects.

Examples:

- Aquarium setups for air and water lines

- Cable organization for home theater systems

- Decorative tubing for craft projects

4. Food and Beverage Industry

- Food-grade variants of smoke-vinyl-tubing are used in the food and beverage industry for transferring liquids and gases.

Examples:

- Beer and wine dispensing lines

- Soda fountain systems

- Water filtration systems

5. Medical Applications

- Smoke-vinyl tubing is also used in certain medical and laboratory applications due to its clarity and flexibility.

Examples:

- Fluid transfer in non-critical medical devices

- Protective covering for sensitive medical equipment

- Laboratory tubing for chemical handling

Types of Smoke Vinyl Tubing

1. Standard Smoke Vinyl Tubing

- This is the most common type, suitable for general-purpose applications like fluid transfer and cable protection.

Features:

- Flexible and lightweight

- Resistant to abrasion and minor chemicals

- Semi-transparent for content visibility

2. Reinforced Smoke Vinyl Tubing

- Reinforced variants are designed to handle higher pressure and more demanding environments.

Features:

- Embedded with a mesh or spiral for added strength

- Handles higher pressures and temperatures

- Suitable for industrial and automotive uses

3. UV-Resistant Smoke Vinyl Tubing

- Specially designed to withstand prolonged exposure to sunlight, making it ideal for outdoor applications.

Features:

- UV-resistant coating

- Prevents cracking and discoloration from sunlight

- Long-lasting even in harsh environmental conditions

4. Food-Grade Smoke Vinyl Tubing

- Certified for safe use with food and beverages, this tubing complies with FDA regulations.

Features:

- Non-toxic and odor-free

- Resistant to staining and bacterial growth

- Smooth interior surface for easy cleaning

Benefits of Using Smoke Vinyl Tubing

1. Visibility: The smoke tint allows partial visibility, enabling users to monitor flow or check for blockages.

2. Durability: Designed to withstand wear, tear, and environmental factors, ensuring long-term performance.

3. Flexibility: Easy to handle and install, even in tight or complex setups.

4. Cost-Effectiveness: Affordable compared to other types of specialized tubing without compromising performance.

5. Versatility: Suitable for a wide range of applications, from industrial to household use.

6. Aesthetic Appeal: Its sleek, semi-transparent finish adds a professional look to any setup.

How to Choose the Right Smoke Vinyl Tubing

1. Identify the Application

- Determine the specific use for the tubing. For industrial applications, reinforced or UV-resistant variants may be necessary. For food-related uses, ensure the tubing is food-grade certified.

2. Consider Size and Thickness

- Choose tubing with the appropriate diameter and wall thickness to handle the intended flow or pressure.

3. Check Material Compatibility

- Ensure the tubing material is compatible with the substances it will carry, whether liquids, gases, or electrical cables.

4. Assess Environmental Factors

- Consider exposure to UV light, temperature extremes, or abrasive conditions and choose a variant designed to withstand these factors.

5. Evaluate Aesthetics and Visibility

- For applications where appearance matters, the sleek smoke tint can be an added advantage.

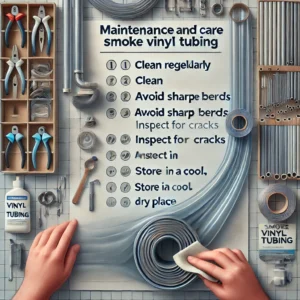

Maintenance and Care Tips

1. Regular Cleaning: Clean the tubing periodically to prevent blockages or buildup, especially in food and beverage applications.

2. Inspect for Wear: Check for cracks, discoloration, or loss of flexibility, which may indicate the need for replacement.

3. Avoid Sharp Bends: Although flexible, excessive bending can weaken the tubing over time. Use appropriate clamps or guides to secure it.

4. Store Properly: Store unused tubing in a cool, dry place to prevent degradation from UV exposure or extreme temperatures.

5. Replace When Necessary: Damaged tubing should be replaced immediately to avoid leaks or operational failures.

Environmental Impact of Smoke Vinyl Tubing

1. Sustainability Concerns

2. Reprocessing Options

3. Eco-Friendly Alternatives

Sector Standards and Certifications

1. FDA Compliance for Food and Beverage Applications

2. RoHS and REACH Compliance

3. NSF Certification for Drinking

Personalization and Bulk Purchasing Tips

1. Getting Custom Sizes

2. Bulk Purchasing Discounts

3. Different Colors and Branding Options

Innovations in Smoke Vinyl Tubing

1. Enhanced UV Resistance

- Advanced coatings now offer improved protection against UV degradation, extending the lifespan of tubing used in outdoor applications.

2. Eco-Friendly Alternatives

- Manufacturers are developing PVC-free smoke tubing options to meet increasing environmental and regulatory demands.

3. Antimicrobial Coatings

- Food-grade and medical tubing options now feature antimicrobial coatings to enhance hygiene and safety.

4. Customizable Solutions

- Companies offer customization in terms of size, color, and reinforcement to meet specific industry needs.

Top Manufacturers of Smoke Vinyl Tubing:

When purchasing smoke-vinyl tubing, it’s important to choose reliable manufacturers known for quality and compliance with industry standards.

Here are a few leading brands:

- Eldon James: Offers food-grade and industrial-grade vinyl tubing with various custom options.

- New Age Industries: Renowned for its high-quality PVC tubing suitable for diverse applications.

- Hudson Extrusions: Specializes in custom tubing solutions, including smoke vinyl variants.

- Freelin-Wade: Provides durable and flexible vinyl tubing with excellent chemical resistance.

Technical Specifications of Smoke Vinyl Tubing

When choosing smoke vinyl tubing, look at the adhering to specs to guarantee being compatible along with your application:

1. Material Composition

- Helped make from polyvinyl chloride (PVC) along with plasticizers for versatility.

- Some variants include reinforcement layers (braided or spiral-wound) for added durability.

- May be created to be food-grade, UV-resistant, or even chemical-resistant based upon designated usage.

2. Temp Range

- Typical smoke vinyl tubing: -20 ° F to 150 ° F( -29 ° C to 65 ° C).

- Bolstered versions: Can manage slightly much higher temperatures, around 180 ° F( 82 ° C ).

- Certainly not appropriate for extreme heat uses like steam transmission– make use of plastic or PTFE tubing as an alternative.

3. Tension Ratings

- Standard tubing: 20-40 PSI (extra pounds every square inch), depending upon dimension.

- Bolstered tubing: Up to 250 PSI, making it suitable for commercial and auto requests.

- Higher pressure rankings demand added encouragement like knotted or fiber-mesh layers.

4. Interior Diameter (ID) and Outer Diameter (OD).

- Typical sizes:. 1/4″ I.D. x 3/8″ OD– Ideal for tiny fluid or even fuel lines.

- 3/8″ ID x 1/2″ OD– Used in pneumatic systems and cord protection.

- 1/2″ ID x 3/4″ OD– Suitable for commercial fluid transactions. Personalized sizes on call coming from producers for specialized requests.

5. Hardness (Durometer Rating).

- Bank A 60-75: Flexible yet tough for liquid transmission and wire defense.

- Much higher durometer (80+) possibilities available for additional stiff, wear-resistant functions.

FAQS frequently asked :

Q1.Does vinyl have more strength than PVC or PVC-based plastics?

- PVC tubing is more flexible and softer than vinyl. Vinyl is more flexible and softer, making it ideal for use under low pressure.

Q2.Is vinyl tubing suitable for use with hot water?

- Vinyl tubing can lose its shape or soften when exposed to hot water. For hot water, use heat-resistant tubes like reinforced or silicone hoses.

Q3.How is vinyl tube used?

- Due to its transparency and flexibility, vinyl tubing can be used in aquariums, for food and beverage tubes, gas and air transfer, gardening and other light chemical applications.

Q4.Can I use vinyl tubing for oil?

- Vinyl tubing can be used for lighter oils, but is not suitable for heavier or petroleum-based oil. Oil can degrade the tubing over time. It’s therefore best to choose specialized oil-resistant tubing.

Q5.Is vinyl safe for drinking?

- If the vinyl tubing is marked “food grade” and “potable Water Safe”, it can be used to drink water. Vinyl tubing does not contain any chemicals that could leach into the water.

Q6.PVC tube and vinyl tube are the same thing?

- There is vinyl tubing. Vinyl tube, which is a flexible PVC pipe type, can be found. The two polyvinylchlorides are the same, but standard PVC is more rigid and used for high pressure applications.

Conclusion

Smoke-vinyl-tubing is a versatile and cost-effective solution for a wide range of applications. Its durability, flexibility, and sleek appearance make it a popular choice for industries such as automotive, industrial, and food and beverage. By understanding the properties, types, and benefits of smoke vinyl tubing, you can select the right product for your specific needs.

Whether you’re managing fluid systems in an industrial setup or organizing cables for a home project, smoke vinyl tubing

Delivers performance, reliability, and aesthetic appeal. With advancements in material technology, the future of smoke vinyl tubing promises even greater adaptability and functionality.

I learned a lot from your content thank for such valuable content