The Ultimate Guide to Tubing Clamps:

Types, Applications, and Selection Tips

The following is a brief introduction to the topic:

Tubing clamps are essential tools for tubing that are widely used to secure tubing or pipes. Tubing clamps ensure that connections are reliable and secure whether you’re working on a project for an industry projects or equipment management, performing medical procedures, etc. This guide provides an overview of tubing clamps. This guide includes information on their types and uses, as well as advice for choosing the right one.

What is a Tubing Clamps?

Tubing clamps are used to secure and protect or control the flow and passing of liquid through tubes. These tubing clamps are used in many applications where a solid connection is needed. They come in different sizes, materials and designs that fit various types of tubing clamps you need . Tubing Clamps are used by industries like automotive and vehicle , plumbing applications, and medical manufacturing.

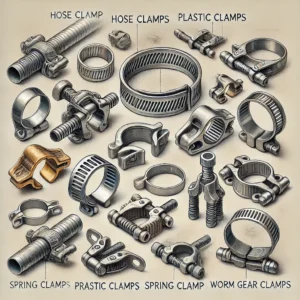

Types of Tubing Clamps

- Hose Clamps

- Design Metal band tightening around tube with screw mechanism.

- The Best for: Secure hoses used in automotive and industrial applications, plumbing, or other industries.

- How it Works Turn the screw until the clamp is tightened around the hose. This will ensure a leakproof seal.

- Advantages Durable, adjustable and capable of withstanding pressures up to a certain level.

- Limitations : Not suitable for fragile or soft tubing.

- Spring Clamps

- Design: A simple spring-loaded mechanism made from flexible metal.

- Best For: Low-pressure applications and temporary connections.

- How It Works: Squeeze the clamp’s ends together to expand it, then release to grip the tubing.

- Advantages: Easy to install and remove, reusable.

- Limitations: Limited adjustability and not ideal for high-pressure scenarios.

- Pinch Clamps

- Design Metal or plastic clip with a one-time use design.

- The Best For Permanent or semi-permanent connectors, particularly in PEX systems.

- It’s Working Use the specialized tool for crimping and locking in place.

- Benefits Creates an encrypted and secure connection.

- Restrictions Cannot be re-used and require a specific tool for crimping.

- Plastic Tube Clamps

- Design Lightweight, corrosion-resistant plastic clamps.

- Best for: Light-duty medical, laboratory and other applications.

- How it Works : Snap or tighten tubing manually.

- Advantages Non-corrosive and chemically resistant.

- Limitations : This product is not suitable for high pressure or heavy duty applications.

- Saddle Clamps

- Design: Semi-circular clamp with mounting holes.

- Best For: Anchoring tubing or pipes to walls or structures.

- How It Works: Screw the clamp onto a surface to hold tubing in place.

- Advantages: Provides stable and permanent support for tubing.

- Limitations: Fixed position, not adjustable once installed.

- Quick-Release Clamps

- Design: A clamp with a lever or latch for easy tightening and loosening.

- Best For: Applications requiring frequent adjustments or removals.

- How It Works: Flip the lever to tighten or release the clamp.

- Advantages: Convenient and time-saving.

- Limitations: May not provide as tight a seal as other types.

- Step Clamps

- Design: A flexible clamp with ridges or steps for incremental adjustment.

- Best For: Situations where precise tightening is needed.

- How It Works: Slide the tubing through the steps and lock it in place.

- Advantages: Adjustable and suitable for various diameters.

- Limitations: Typically used for lightweight applications.

- Ear Clamps

- Design: A clamp with a “ear” that is crimped to tighten.

- Best For: Securing hoses in plumbing and automotive applications.

- How It Works: Use a specialized tool to squeeze the ear and tighten the clamp.

- Advantages: Compact and provides uniform pressure.

- Limitations: Requires specific tools and is single-use.

Common Applications of Tubing Clamps

- Plumbing

- Securing hoses and pipes in residential and industrial water systems.

- Used in applications such as sealing leaks, joining hoses, and ensuring water-tight connections.

- Automotive

- Fastening fuel, coolant, and air hoses in vehicles.

- Ensures safety and reliability in high-vibration environments.

- Medical and Laboratory Use

- Regulating fluid flow in IV lines, laboratory tubing, and other precision applications.

- Essential for ensuring sterile and precise operation in medical devices.

- Industrial Equipment

- Maintaining stable connections in hydraulic and pneumatic systems.

- Used in heavy machinery and manufacturing lines to prevent downtime.

- DIY Projects

- Holding tubing or pipes securely in various home improvement and creative projects.

- Examples include irrigation systems, aquarium setups, and custom builds.

- HVAC Systems

- Securing ducts and tubing in heating, ventilation, and air conditioning installations.

- Helps prevent air or coolant leaks in the system.

Read About :Hose And Clamp

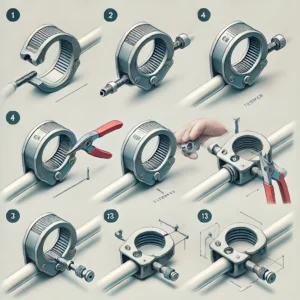

How to Use a Tubing Clamp

- Prepare the Tubing

- Ensure the tubing is clean and cut to the desired length.

- Check for compatibility between the clamp and tubing size.

- Position the Clamp

- Slide or place the clamp over the tubing before connecting it to a fitting or structure.

- Ensure the clamp is aligned correctly to avoid uneven tightening.

- Tighten the Clamp

- For screw or pinch clamps, use the appropriate tool to tighten securely.

- Avoid over-tightening to prevent damaging the tubing or the fitting.

- Test the Connection

- Check for leaks or movement to ensure the clamp is properly secured.

- Adjust as necessary to ensure a firm grip.

- Inspect Over Time

- Periodically check the clamp’s condition, especially in high-stress or corrosive environments.

Tips for Choosing the Right Tubing Clamp

- Material

-

- Stainless Steel : The best for corrosion resistance and durability.

- Plastic : Lightweight, resistant to chemicals and ideal for light duty or medical uses.

- Carbon Steel is a cost-effective steel for general-purpose uses.

- Brass: Its corrosion resistance makes it suitable for chemical applications.

- Size

- To select the correct clamp size, measure the outside diameter of the tube.

-

-

- Consider the thickness of the tubing material.

- Application Requirements

- Consider pressure, temperature, and environmental conditions.

- For outdoor use, choose corrosion-resistant materials.

- Ease of Use

- Choose quick-release or adjustable clamps for applications requiring frequent adjustments.

- Durability

- For permanent connections, opt for heavy-duty clamps with long-lasting materials.

- Cost Efficiency

- Balance quality and cost, especially for projects with high-volume requirements.

- Specialized Features

- Look for clamps with built-in linings to protect soft or delicate tubing.

- Some clamps include color coding for quick identification.

Maintenance Tips for Tubing Clamps

- Inspect Regularly: Check for wear, corrosion, or loosening.

- Clean When Necessary: Remove debris or buildup, especially in industrial or outdoor applications.

- Replace When Worn: Swap out clamps that show signs of rust, cracks, or reduced grip strength.

- Lubricate Moving Parts: Apply light oil to adjustable or screw clamps to prevent sticking.

- Store Properly: Keep unused clamps in a dry, organized space to prevent damage.

Advantages of Tubing Clamps

- Secure Connections: Prevent leaks and ensure stability.

- Versatility: Suitable for a wide range of materials and applications.

- Ease of Installation: Most clamps are simple to install and adjust.

- Cost-Effective: Affordable and reusable in many cases.

- Safety: Reduces the risk of accidental disconnections in critical systems.

- Aesthetic Appeal: Provides a neat and organized appearance in visible installations.

Common Mistakes to Avoid

- Using the Wrong Size

- An improperly sized clamp may fail to secure the tubing effectively.

- Over-Tightening

- Excessive force can damage tubing or compromise its integrity.

- Ignoring Material Compatibility

- Using a metal clamp on a plastic tube without a liner can cause wear and tear.

- Failing to Inspect Clamps Regularly

- Neglecting routine checks can lead to unnoticed wear or damage, resulting in leaks or failures.

- Not Replacing Worn Clamps

- Continuing to use damaged clamps compromises safety and performance.

Conclusion

In a wide range of industries, tube clamps are used to hold pipes, tubes and hoses. The clamps provide a reliable seal, which is essential for any system.. You can increase the health and performance of tubing clamp connections by choosing and maintaining the correct clamp for your tubing. Tubing clamps can be used for vehicle and automotive, industrial projects , and plumbing applications. They are simple but powerful tools that guarantee stability.