The Comprehensive Overview of Vinyl Tubing:

Applications, Advantages, and Acquiring Tips

Vinyl tubing is a cost-effective and practical solution. It is essential in the markets. Worldwide, family members can enjoy the benefits and advantages of vinyl tubing. Vinyl tubing is a versatile material that can be used in countless applications, from pipelines to aquariums. This summary and comprehensive guide will explain what vinyl tubes are and their benefits. We’ll also discuss the features of this tubing, as well as how to choose it for you.

What is Vinyl Tubing?

PVC tubing (Polyvinyl chloride) is also known as vinyl tubing. It’s a lightweight, flexible item that can be used to transport liquids, gasses, or solids. The tubing is made of a polymer known as polyvinyl chloride. This gives it flexibility and strength while still keeping it lightweight and inexpensive.

Secret Features of Vinyl Tubing Quality:

Adaptability:

- Vinyl-tubing can flex and turn without breaking, making it perfect for complicated instalments.

Safe Options:

- Safe for food and clinical usage when accredited.

Sturdiness:

- Resistant to put on, tear, and a lot of chemicals.

Lightweight:

- Easy to deal with and move.

- Often clear, permitting customers to keep track of the circulation is important.

Personalized Sizes:

- Available in numerous sizes and wall surface densities.

Temperature Level Range:

- It can commonly stand up to temperature levels from -20 ° F to 150 ° F.

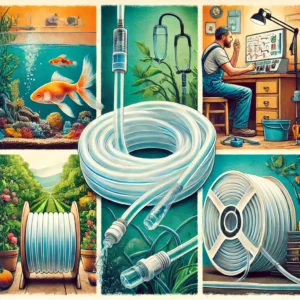

Applications of Vinyl Tubing :

adaptability makes it a favoured selection for a wide variety of applications:

1. Pipes and Water Systems :

- Vinyl-tubing is typically made use of in low-pressure water supplies, such as yard watering, property pipes, and water purification systems. Its adaptability and resistance to moisture make it an outstanding option for transferring water.

2. Fish tanks and Ponds:

- Aquarists depend on clear vinyl-tubing for air pumps, water blood circulation, and filtering systems. Its openness assists check the water circulation, and its safe versions guarantee the safety and security of water life.

3. Food and Beverage Industry

- Food-grade vinyl-tubing is optimal for moving fluids like milk, juice, and beer. Its safe and BPA-free buildings guarantee that it does not infect consumables.

4. Clinical Applications

- Medical-grade vinyl-tubing made use of tools like IV lines, catheters, and oxygen supply tubes as a result of its versatility, clearness, and security.

5. Industrial Use

- Industries make use of vinyl-tubing for chemical transfer, gas lines, and pneumatically-driven systems. Its chemical resistance and resilience make it ideal for rough settings.

6. Do yourself Projects

- From homebrew systems to craft jobs, vinyl-tubing’s convenience makes it a preferred amongst DIY lovers.

Benefits of Vinyl Tubing

1.Cost Effective

- Economical Vinyl-tubing is among one of the most inexpensive choices on the marketplace, providing exceptional worth for its sturdiness and efficiency.

2. Chemical Resistance

- Its capability to stand up to a wide variety of chemicals, consisting of acids, antacids, and oils, makes it ideal for commercial applications.

3. Easy Installation

- The lightweight and versatile nature of vinyl tubing streamlines setup, also in limited rooms or detailed configurations.

4.food grade tubing

- Sanitary Food-grade and medical-grade vinyl tubing alternatives make certain that materials stay unpolluted throughout the transfer.

5.LifeSpan

- Lengthy Lifespan With appropriate upkeep, vinyl tubing can last for several years, decreasing the demand for regular substitutes.

Exactly How to Choose the Right Vinyl Tubing

Picking the ideal vinyl tubing depends upon your details demands. Right here are some variables to take into consideration:

1. Objective of Use:

- Recognize the main function of the tubing.

- For example: The usage of food-grade tubing for consumables. Select enhanced tubing for high-pressure systems.

2. Dimension and Dimensions:

- Take into consideration the internal size (ID), external size (OD), and wall surface density. Guarantee it fits well with the ports and takes care of the needed circulation price.

3. Stress Rating:

- Inspect the stress score to guarantee the tubing can manage the functional stress of your system.

4. Temperature level Tolerance:

- Pick tubing that can hold up against the temperature level of the fluids or gases being moved.

5. Openness:

- For applications like fish tanks or food transfer, clear tubing enables aesthetic surveillance.

6.Qualifications:

- Search for qualifications like FDA authorization for food-grade tubing or ISO criteria for clinical applications.

Read About : Surgical Tubing

Upkeep and Care Tips:

Appropriate upkeep guarantees the durability and effectiveness of vinyl-tubing:

- Routine Cleaning: Clean the tubing occasionally to stop accumulation or clogs. Clear for very easy circulation tracking.

- Stay Clear Of Overstretching: Don’t overstretch the tubing throughout the instalment to avoid splits.

- Shop Properly: Keep extra tubing in a trendy, completely dry location to stay clear of UV and warm direct exposure.

- Check for Wear: Regularly look for indicators of wear, such as staining, splits, or leakages.

Leading Vinyl Tubing Products

1. Clear PVC Vinyl-Tubing

- Perfect for fish tanks

- horticulture

- DIY tasks.

2. Food-Grade Vinyl-Tubing

- Ideal for aquariums, gardening, and DIY projects.

- Transparent for easy flow monitoring.

3. Strengthened Vinyl-Tubing

- Made for high-pressure applications.

- Attributes intertwined or split supports for additional toughness.

4. Medical-Grade Vinyl-Tubing

- Ideal for clinical tools.

- Sterile and non-toxic.

Usual Questions About Vinyl-Tubing

1. Is vinyl tubing secure for alcohol consumption water?

- Yes, food-grade vinyl-tubing is risk-free for alcohol consumption, water and various other consumables. Guarantee it’s licensed as BPA-free and FDA-approved. Clean site, rile and safe.

2. Can vinyl tubing take care of warm fluids?

- Vinyl-tubing can take care of temperature levels as much as 150 ° F. For greater temperature levels, take into consideration alternate products like silicone tubing.

3. how do I gauge vinyl-tubing?

- Procedure the internal size (ID), external size (OD), and wall surface density to guarantee compatibility with your ports.

4. Is vinyl tubing UV-resistant?

- Standard vinyl tubing may degrade with prolonged UV exposure. Opt for UV-resistant variants for outdoor applications.